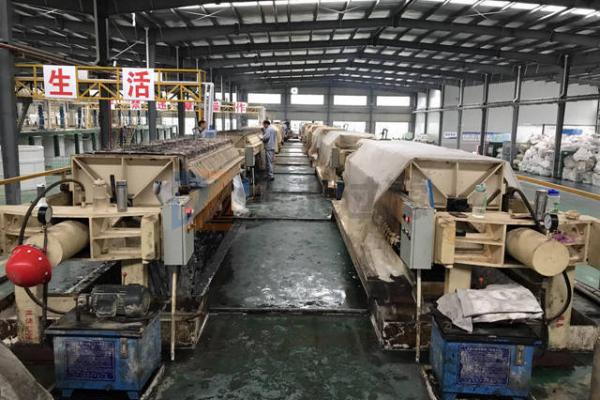

Chamber Filter Press

- 30-1000

- 870、1000、1250、1500、2000

- Auto/Semi-automatic/Manual

- Quick Open, etc.

- 0.6-4.0

- Visible/Invisible

Equipment Selection Parameter Table

Advantages:

1. Short filtration cycle and high efficiency.

2. It has higher cost performance, lower running cost.

3. Simple operation, wide application, the most popular type in the market.

Disadvantages:

1. Intermittent operation, long filtration cycle, and limited continuous processing capacity.

2. Limited automation; requires the addition of automatic plate pulling and cleaning systems for fully automatic operation.

3 . Requires a large footprint and has certain requirements for the installation site.

Applications:

Slurry dewatering for wastewater treatment, Food&beverage, Chemicals, Mining, Medicine, Ceramic slurry, Metallurgy, printing & dyeing, etc.Box-type filter presses are widely used in environmental protection and wastewater treatment, the chemical industry, mining and metallurgy, building materials, and food and biotechnology industries. They are primarily used for industrial wastewater treatment, municipal and industrial sludge dewatering, product filtration, tailings dewatering, and slurry treatment, achieving solid-liquid separation, sludge reduction, resource recovery, and compliance with discharge standards. Their application is most widespread in the field of environmental protection and wastewater treatment. The Chamber filter press is a filtration equipment that is widely used for solid-liquid separation.