Security filters are primarily used to remove small particles from liquids (such as suspended solids, colloids, and microorganisms), protecting downstream equipment (such as reverse osmosis membranes and ion exchange resins). Their design and selection require comprehensive consideration of factors such as fluid properties, filtration accuracy, flow rate, pressure drop, and material compatibility. The following are the core steps and key points for design and calculation:

I. Design Steps

1. Clarify Filtration Requirements

Filtration medium: Liquid (water, oil, chemical solutions).Target pollutants: Particle type (e.g., sand, rust, microorganisms), particle size range, concentration.

Filtration accuracy: Typically 1-100 micrometers (commonly 1μm, 5μm, 10μm), determined according to downstream equipment requirements.

Flow rate requirements: Maximum/minimum flow rate (m³/h or L/min). Operating conditions: Temperature, pressure (working pressure and maximum allowable pressure), pH value, and chemical compatibility.

2. Select Filter Type

Cartridge filter: Suitable for high-precision, low-flow scenarios (such as reverse osmosis pretreatment).Bag filter: Suitable for high flow rates and medium precision (10-100μm).

Candle filter: Suitable for high-viscosity or high-solids content media.

Self-cleaning filter: Suitable for scenarios requiring high automation and reduced maintenance.

3. Material Selection

Filter element: Polypropylene (PP), polytetrafluoroethylene (PTFE), nylon, sintered metal.Housing material: Stainless steel (304/316L), carbon steel (with anti-corrosion lining), PP/UPVC (corrosion-resistant).

4. Determine Filter Element Parameters

Filtration area: Determines dirt holding capacity and pressure drop, calculated based on flow rate.Filter element length: Standard lengths are 10 inches, 20 inches, 30 inches, 40 inches.

Connection type: Clamp type, threaded type, flanged type.

II. Key Calculation and Selection Formulas

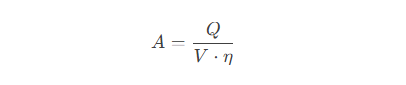

1. Calculation of Filtration Area

A: Total filtration area (m²);

Q: Flow rate (m³/h);

V: Filtration velocity of the filter media (m/h), generally 0.1~0.3 m³/(m²·h) (adjusted according to the type of filter media);

η: Filter element utilization rate (usually 0.8~0.9).

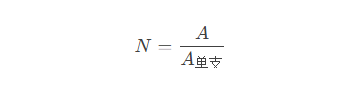

2. Calculation of the number of filter elements

N: Number of filter cartridges;

A (single cartridge): Effective filtration area of a single filter cartridge (provided by the manufacturer, e.g., 0.5~1.5 m²/cartridge).

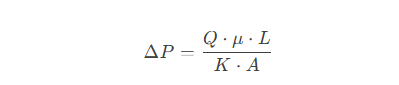

3. Pressure drop estimation

▲P: Initial pressure drop (Pa);

μ: Fluid viscosity (Pa·s);

L: Filter element thickness (m);

K: Permeability coefficient of the filter material (m², requires experimental or manufacturer data). Note: The actual pressure drop will increase with the accumulation of pollutants; a safety margin of 1.5 to 2 times should be reserved.

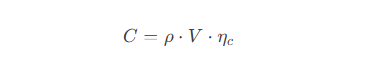

4. Calculation of dirt-holding capacity

C: Contaminant capacity (g);

ρ: Contaminant density (g/m³);

V: Filter element volume (m³); ηc: Filter element porosity (provided by the manufacturer, e.g., 60%~90%).

III. Selection Key Points

Filtration accuracy matching: Downstream equipment requirements: For example, reverse osmosis systems require an accuracy of less than 5μm. Actual particle distribution: Select a reasonable accuracy level through particle counter testing.Flow rate and pressure drop balance: Excessive flow rate may lead to excessively high pressure drop or shortened filter element life. Select the number and area of filter elements based on system pressure limitations.

Chemical compatibility verification: Filter materials and sealing materials must be resistant to media corrosion (refer to the chemical compatibility table).

Maintenance and cost optimization: Filter element replacement frequency: In high-pollution scenarios, choose large-capacity filter elements or self-cleaning designs. Economic efficiency: Compare the long-term costs of disposable and washable filter elements.

IV. Precautions

Pre-filtration protection: Install a coarse filter (such as 100μm) before the security filter to extend the filter element life.Ventilation and drainage: The housing design should consider vent valves and drain valves to avoid air blockage and sedimentation.

Verification testing: Through bubble point test (to verify filter element integrity) and particle retention rate test.

Safety margin: It is recommended to provide 10%~20% more filter elements to cope with sudden pollution or flow fluctuations.