Cast Iron Filter Press

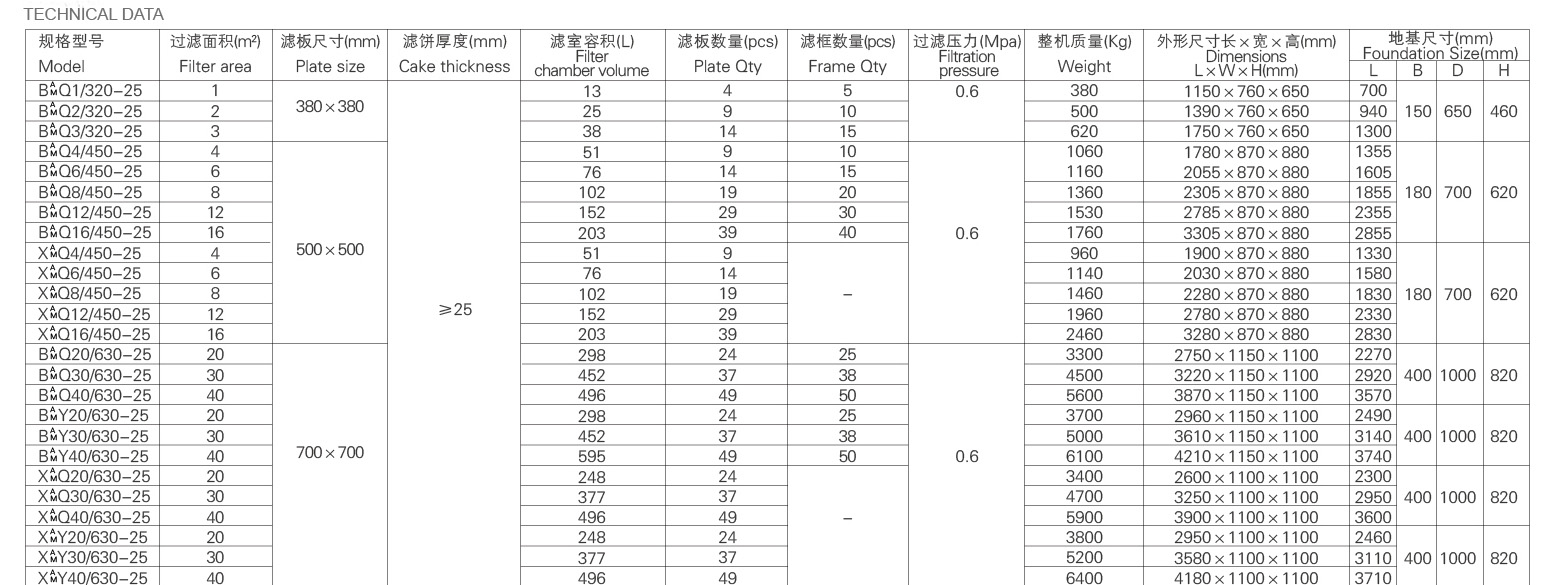

- 1-80

- 380、500、700、800

- Auto/Manual

- Quick Open, etc.

- 0.6

- Visible/Invisible

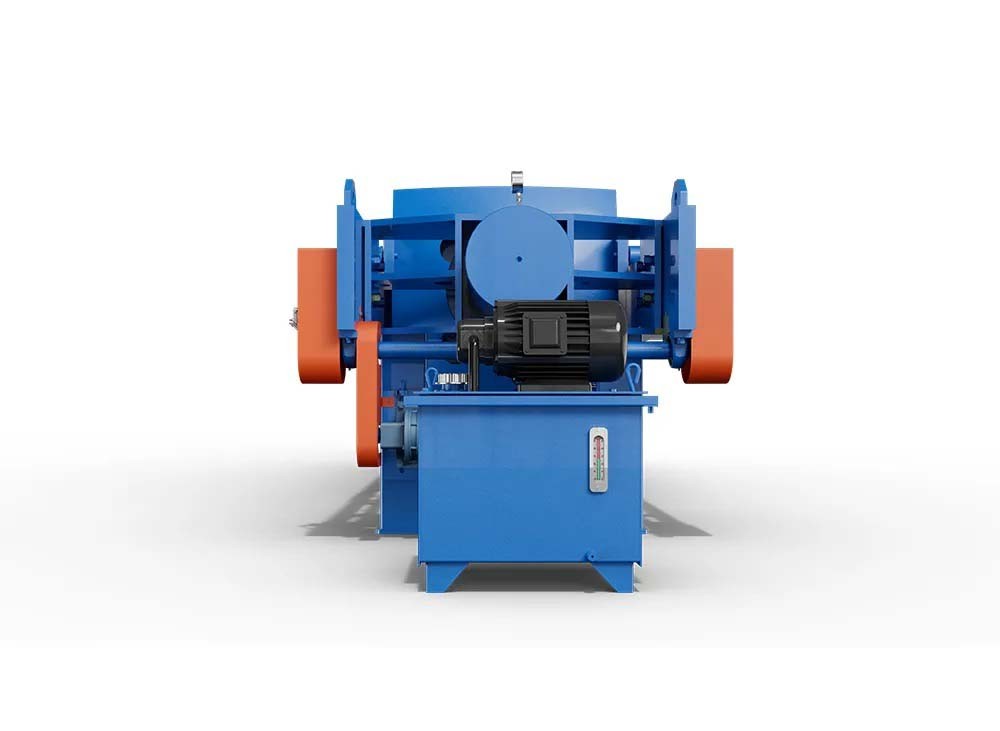

Some materials have very high temperatures, for example, 120 ℃ or higher. Thus, the normal PP filter press cannot work well, and we have to consider the cast-iron filter press. This equipment and its filter plates are made of high-quality nodular cast iron.

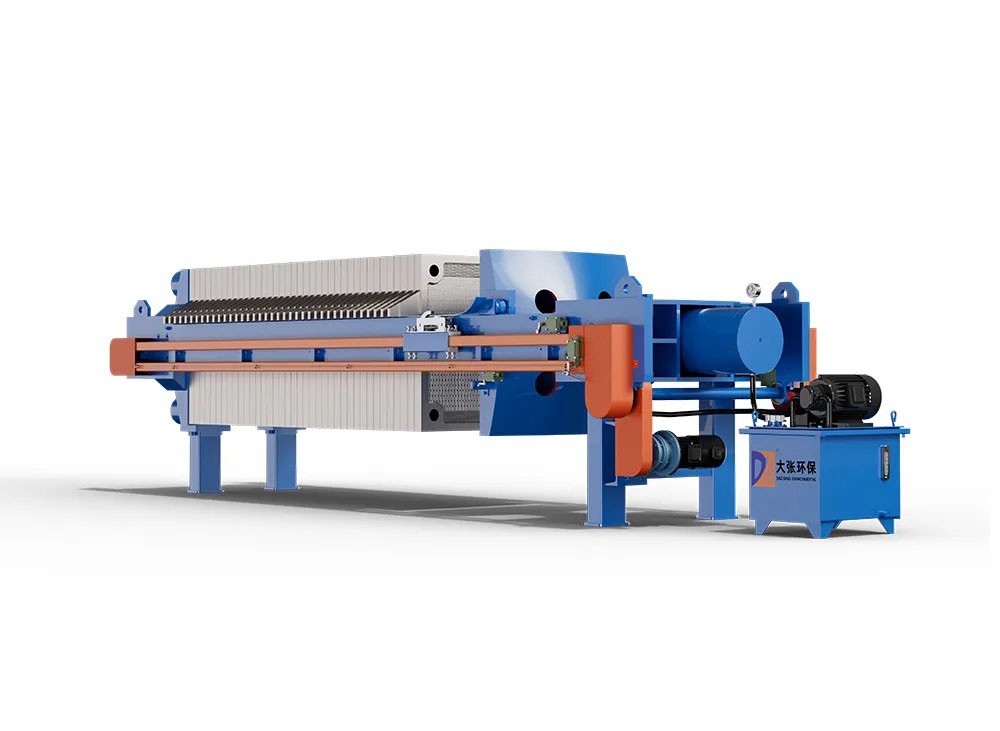

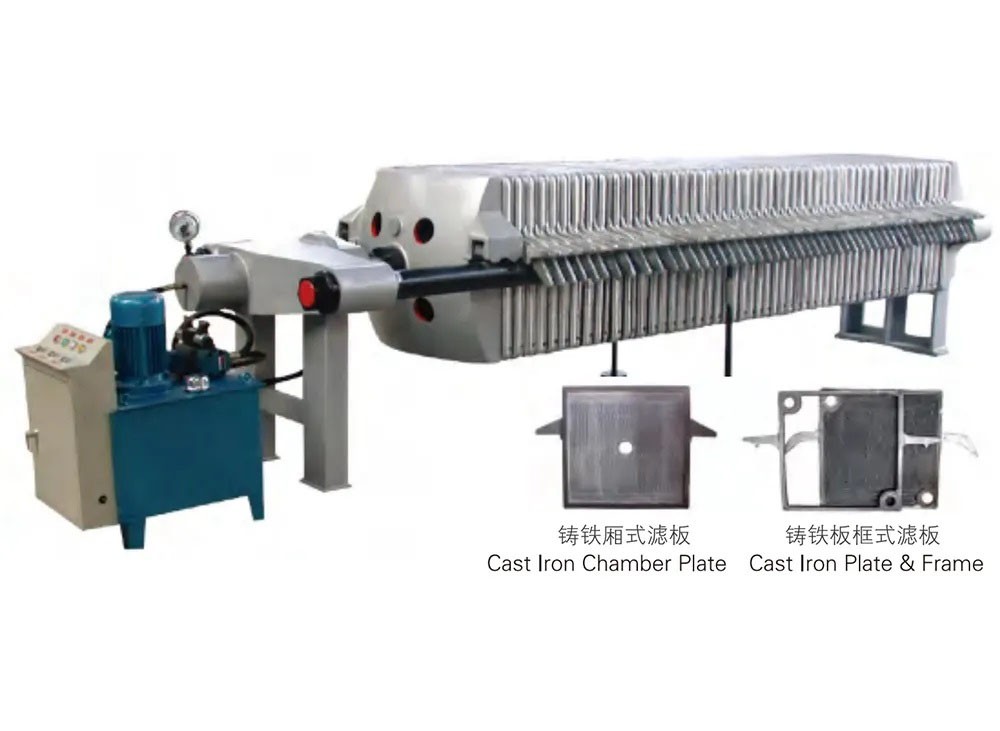

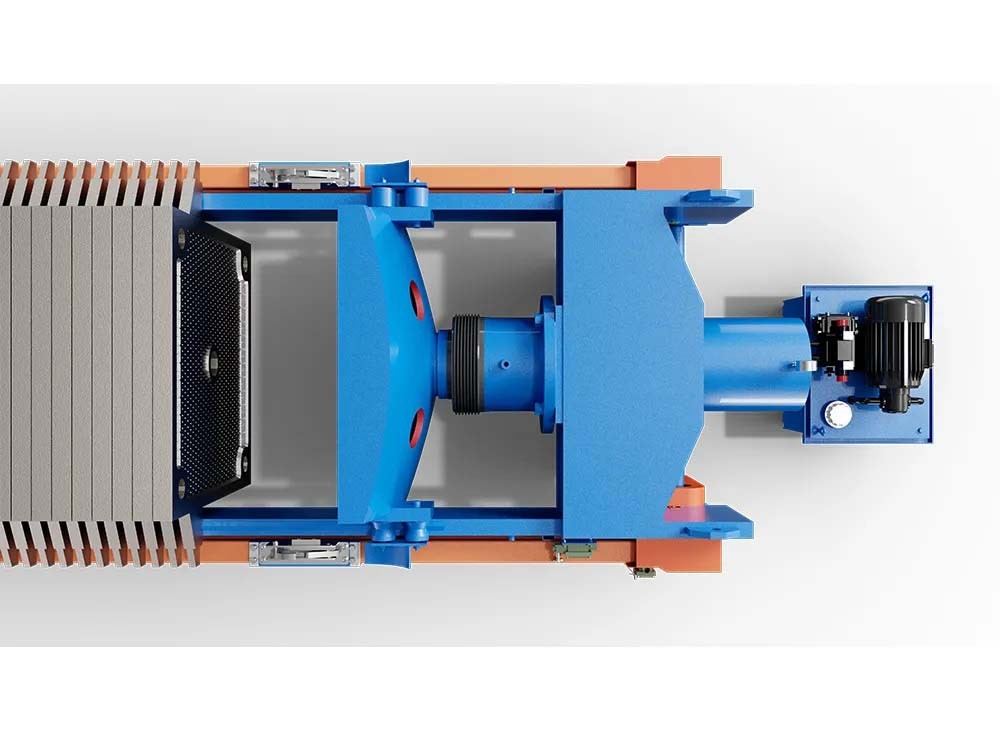

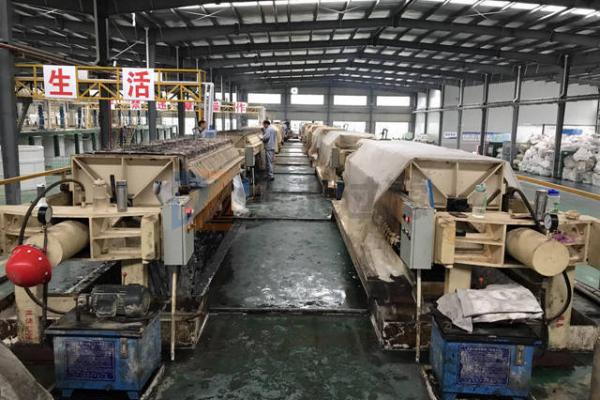

According to the cake discharging method, cast iron filter presses have an automatic type and a manual type. Because of the difference from the PP filter press plate, the cast iron filter plate is very heavy and not easy to move by manpower, so normally, if the filter plate size is over 630mm, we will recommend the automatic cast iron filter press to save labor. And there are two plate types for different filtering demands: chamber type and plate & frame filter plates. Normally, a cast iron filter press adopts motor-driven hydraulic closing to get a better clamping effect.

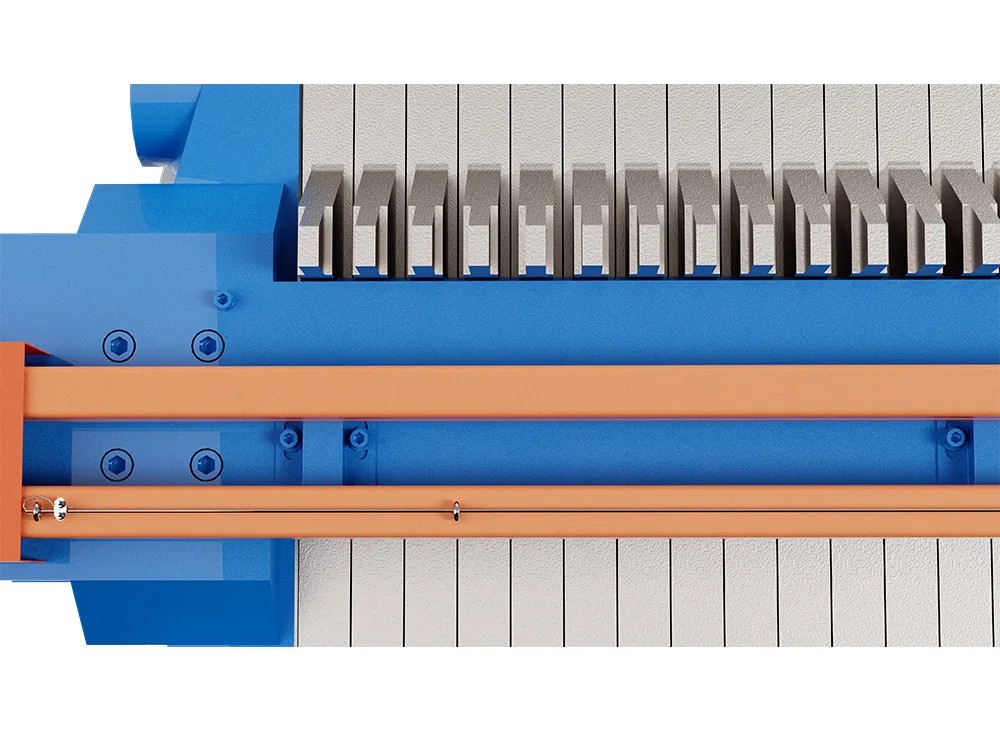

In fact, besides the middle plate pack, its head plate and tail plate are also made of nodular cast iron. Our cast iron plate filter press adopts advanced casting technology, so it has the best wear resistance. To ensure the best quality, every steel filter plate will be milled, which ensures a smooth surface. Only in this way can it have better chamber sealing performance to bear higher filtering pressure. If your material is flammable, we can adopt an anti-explosion design. Please contact us for the filter press manufacturer's price.