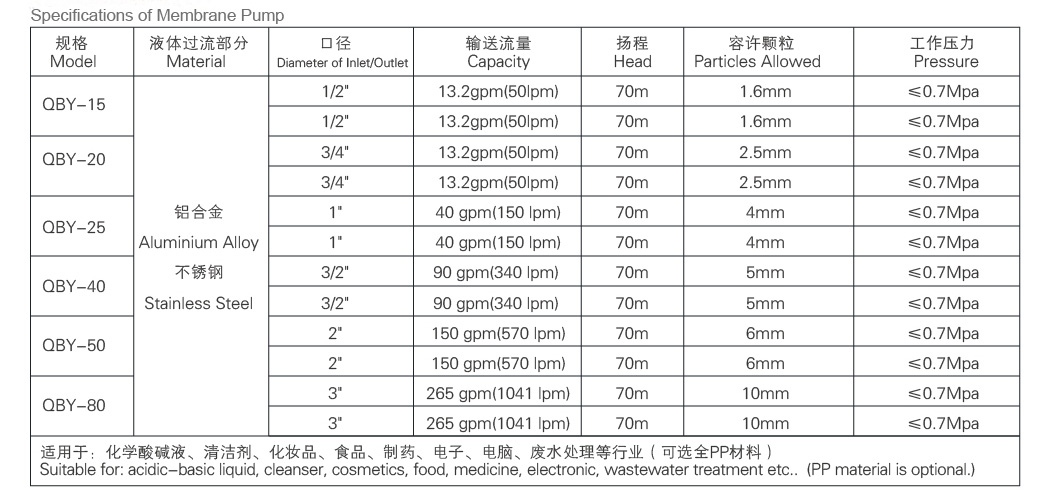

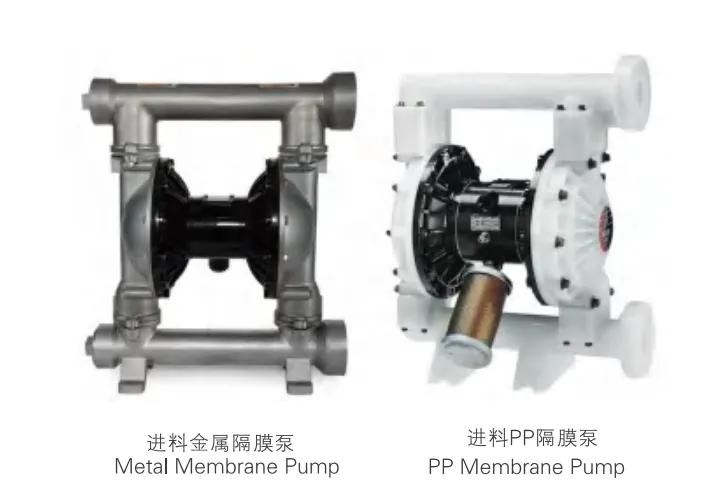

Diaphragm pump

Main Features

Leak-free Design: The diaphragm pump isolates the liquid from the mechanical parts through the diaphragm, ensuring excellent sealing and reducing the risk of leaks.

Strong Adaptability: It can handle liquids of various viscosities and corrosiveness, making it suitable for a wide range of industrial applications.

Self-priming Capability: The pump has good self-priming ability, effectively processing slurries containing bubbles or solid particles.

Easy Maintenance: With a simple structure, the pump is easy to disassemble and clean, reducing maintenance costs and time.

Applications

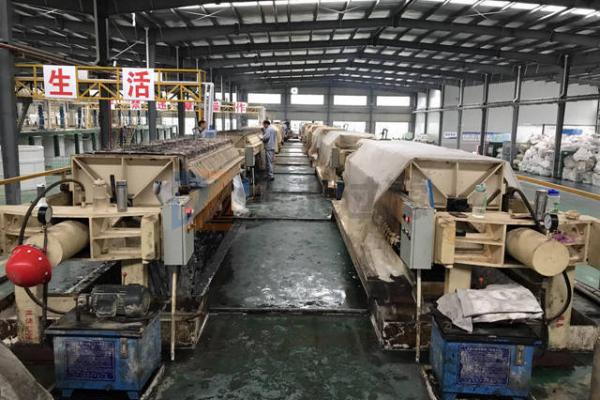

Mining: Used for transporting slurry and tailings, helping to efficiently deliver liquids containing solid particles to the filter press for solid-liquid separation.

Wastewater Treatment: In the environmental protection industry, diaphragm pumps are often used for sewage and wastewater treatment, facilitating solid sedimentation during the treatment process.

Food and Pharmaceutical Industries: Suitable for transporting various food and pharmaceutical raw materials, ensuring hygiene and safety in the production process.

Chemical Industry: Used for transporting corrosive chemical media, meeting strict requirements for fluid control.

Summary

With its efficiency, safety, and flexibility, the diaphragm pump has found extensive applications in the filter press industry. Proper selection of a diaphragm pump can significantly enhance the working efficiency of filter presses, optimize the solid-liquid separation process, and improve overall production outcomes.