Slurry pump

Main Features

Abrasion-resistant materials: Slurry pumps are typically made from highly abrasion-resistant alloys or rubber materials to withstand wear and corrosion, extending the pump's lifespan.

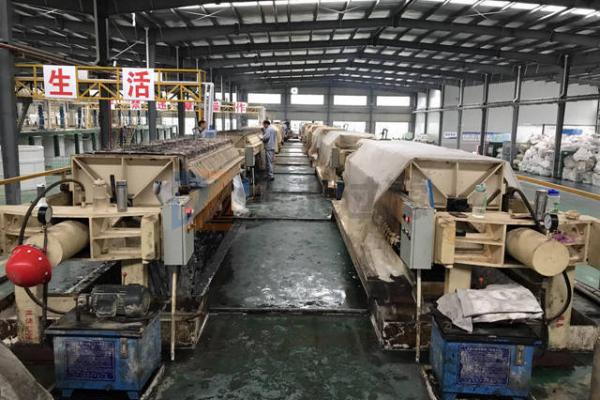

Powerful conveying capacity: Capable of processing slurries with high solid content, ensuring stable flow and pressure during the filter press operation.

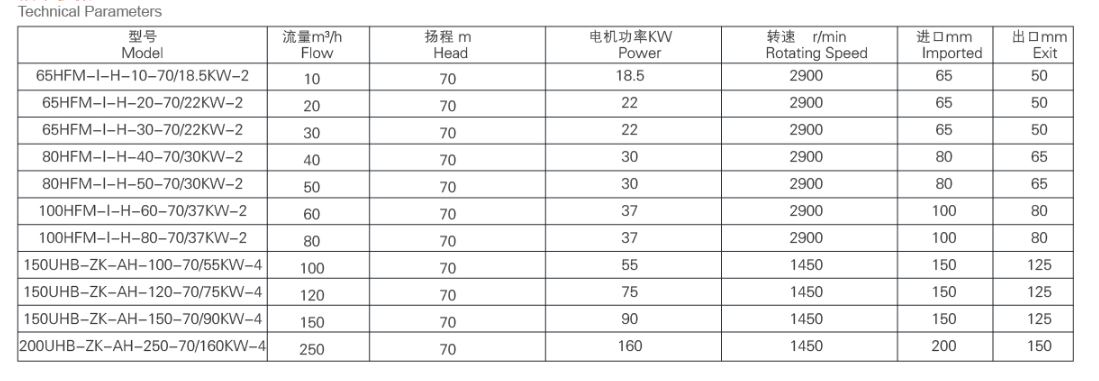

Multiple configurations: Available in various models and specifications to meet different operational needs, adaptable to different types of filter presses.

High efficiency: Optimized fluid dynamics design reduces energy loss and enhances conveying efficiency.

Applications

Mining: Used to transport mineral-rich slurries to the filter press for dewatering, recovering solid minerals during the ore beneficiation process.

Coal Industry: Employed in the treatment and dewatering of coal slime, improving coal resource recovery rates.

Environmental Engineering: In wastewater treatment, it handles wastewater containing sediment, assisting in the separation and removal of solid waste.

Construction Industry: Utilized for the transportation of materials such as concrete and mortar, ensuring a steady supply of materials during construction.

Summary

The slurry pump is an indispensable piece of equipment in the filter press industry. Its superior performance and wide range of applications allow it to excel in handling liquids containing solid particles, significantly increasing production efficiency and reducing operating costs. Choosing the right slurry pump will provide a solid foundation for the efficient operation of filter presses.