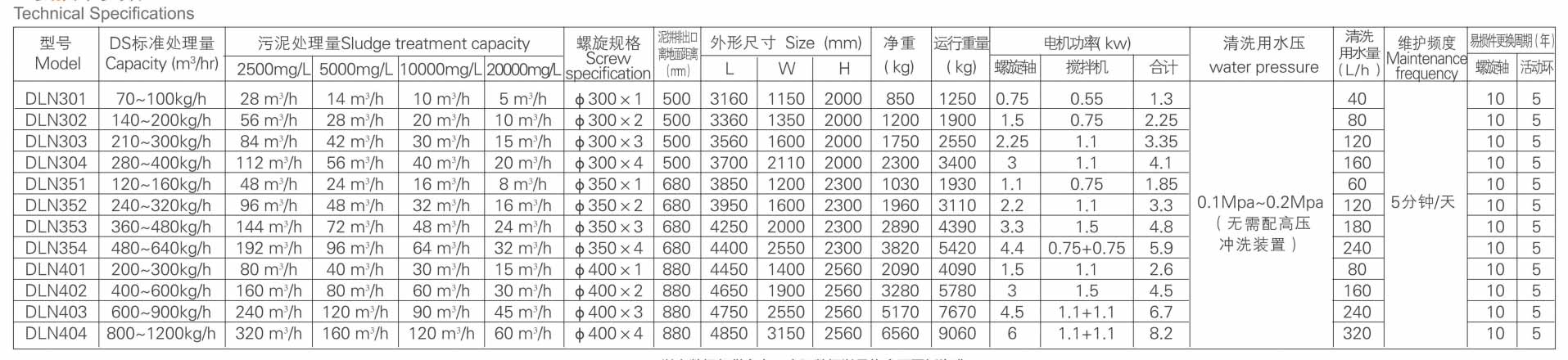

Stacked sludge thickener

- DLN301-404

- 70-1200

- 300x1-400x4

- 0.1~0.2

Work Principle

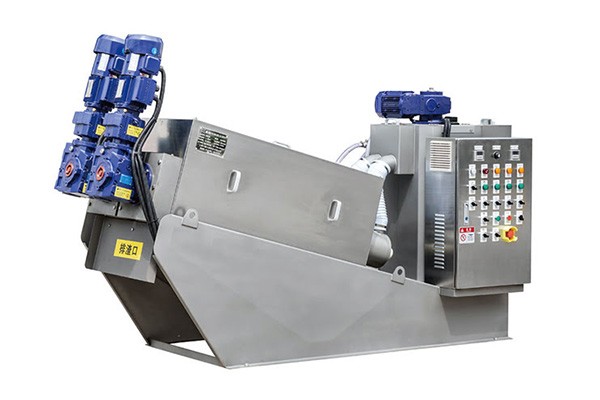

The sludge thickening screw press is composed of a thickener, a driving device, a filtrate tank, a mixing system, and a frame. When the screw press is working, the sludge

is pumped to the mixing tank by the sludge pump. In the meantime, the dosing pump also quantitatively transports the polymer to the mixng tank, then the string motor

drives agitator to start mixing until solid particles are flocculated, When the liauid level reaches the uoper

level of the liquid level sensor, the sensor gets a signal anc

instructs the main motor of screw press to work, thereby starting to filter and press the sludge that comesinto the screws body. Under the squeezing of the screw shaft,

the sludge is raised step by step to the sludge outlet, and the fitrate flows out from the gap between the fixed rina and the moving ring.

Technical Features

The sludge thickening range is wide, and it is applicable to sludge consistency ranges from 98% to 99.8%. The concentrate of thethickened sludge is stable and adjustable in the range of 90-96%. High concentration efficiency and small land space. No filter cloth, self-cleaning, no clogging, no need for high-pressure washing water. Low speed operation, low energy consumption, low operating cost, no vibration, no noise. Closed operation reduces odor emissions. Few vulnerable parts, low maintenance cost, and long service life. Fully automatic control, continuous operation, simple maintenance, and management.

Scope of application

As the pretreatment equipment of the sludge deep dewatering system, it is usually matched with uitra-high pressureelastic press, membrane filter press and other sludge deep dewatering equipments. Replace the sludge thickening tank as the pretreatment equipment of the sludge dewatering system. Used in other slurry concentration or solid-liquid separation processes.