PA/PE micrepore precision filter

- 20-870

- L500-L1500

- 1-131

- 1-131

- 40-6000

- 20-200

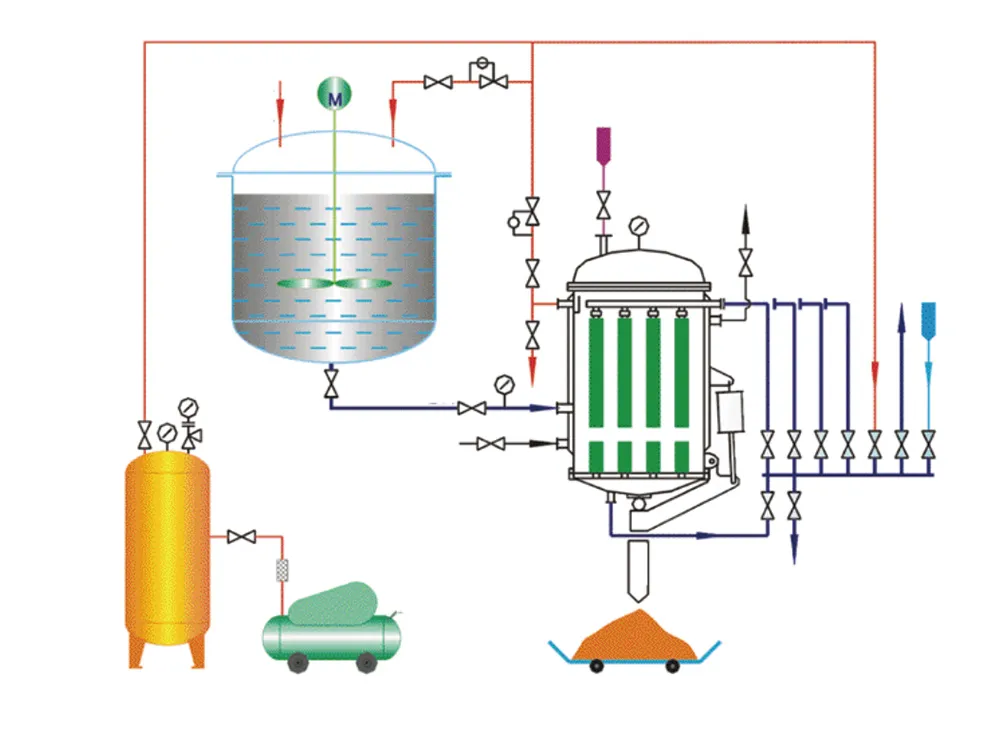

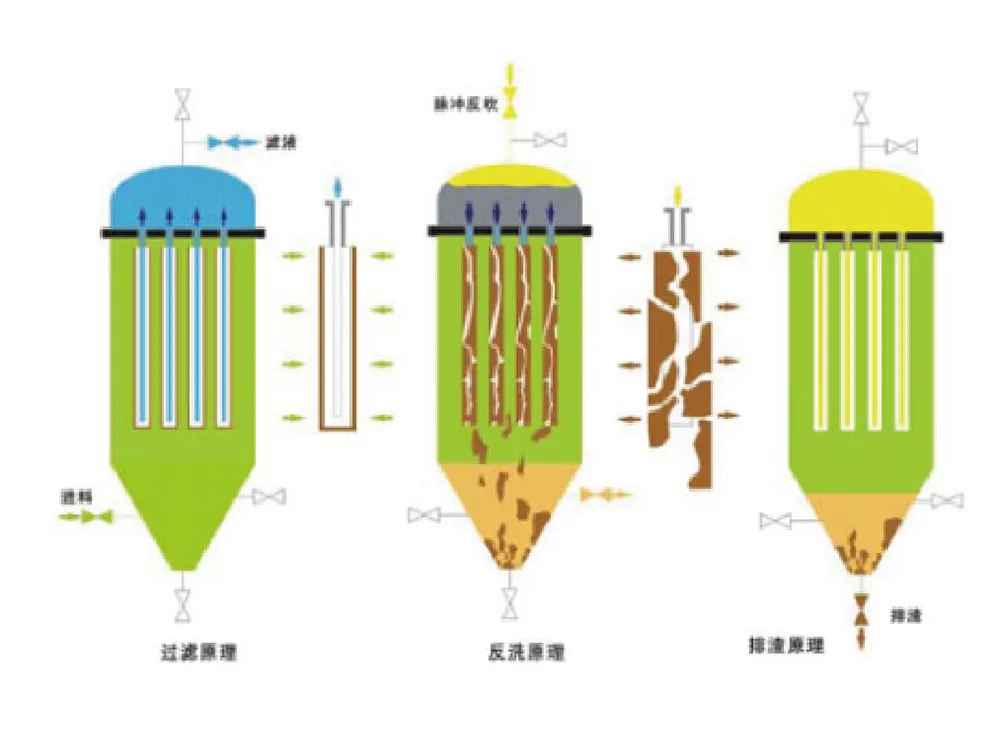

Main Structure and Principle

The medium of the PA/PE micropore filter is the sintered tube. After pretreatment, the wastewater (waste gas) goes through the medium to remove the solids that are bigger than 0.3 ㎛, thus realizing the filtering effect. After filtering is finished, the solids will be conveniently discharged by the air at the bottom, then lift the tubes. The filter is enclosed, so it's safe and has no air leakage. The seals are specially designed in order to fast and efficiently close the discharging port. And the cap does not need to use a lift device to open, so it's easy to clean and maintain.

Applications

It's widely used for wastewater, waste gas in folowing inaustries: medicines, chemical, food, light industry, textle, metallurgy etc., and decoloration (active carbon). It's an ideal equipment to replace some traditional filtering machines.

• High filtering efficiency. For liquid filtering, use a PE/PA tube (special macromolecule) as a medium, and the filtering precision can be 0.1 ㎛. For air filtering, the precision can be 0.3 ㎛, and the separation efficiency can be 99% highly efficient for discharging cakes. It uses the backwash (via air/water) method to regenerate the tubes conveniently.

Best corrosion-resistant performance. It can resist various acids, alkalis, salts, and organic solvents (under 70 °C). And it is nontoxic, flavorless, so it's suitable for the following industries: medicines, food, chemical, water treatment, oilfield flooding, etc.

• Temperature Performance: for PE tube, ≤80°C; for PA tube, ≤ 100°C; for PAC tube, ≤ 120°C