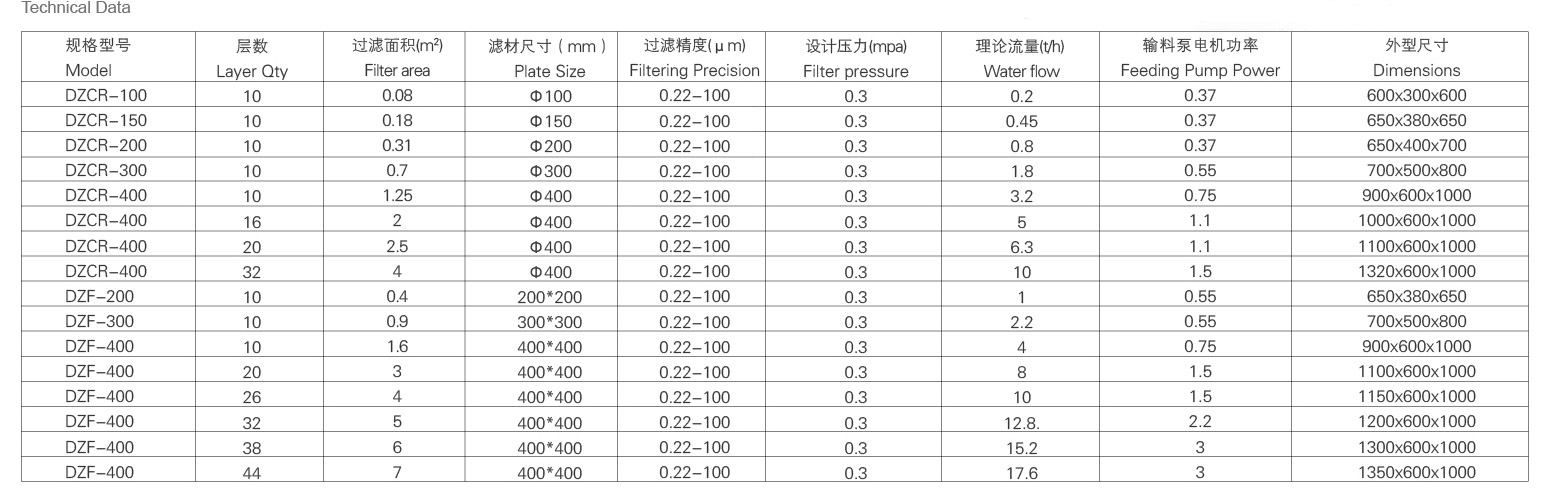

S.S Multi-layer plate frame filter

- 0.08-7

- 100-400

- 0.22-100

- 0.3

- 0.8-23

Working Principle

The suspension is pumped into each sealed filtration chamber of the machine. Under pressure, the filtrate passes through the filtering layer and filter membrane or other filtering materials, and is discharged through the outlet, while the residue forms a filter cake within the plate frame, achieving the purpose of solid-liquid separation.

Features

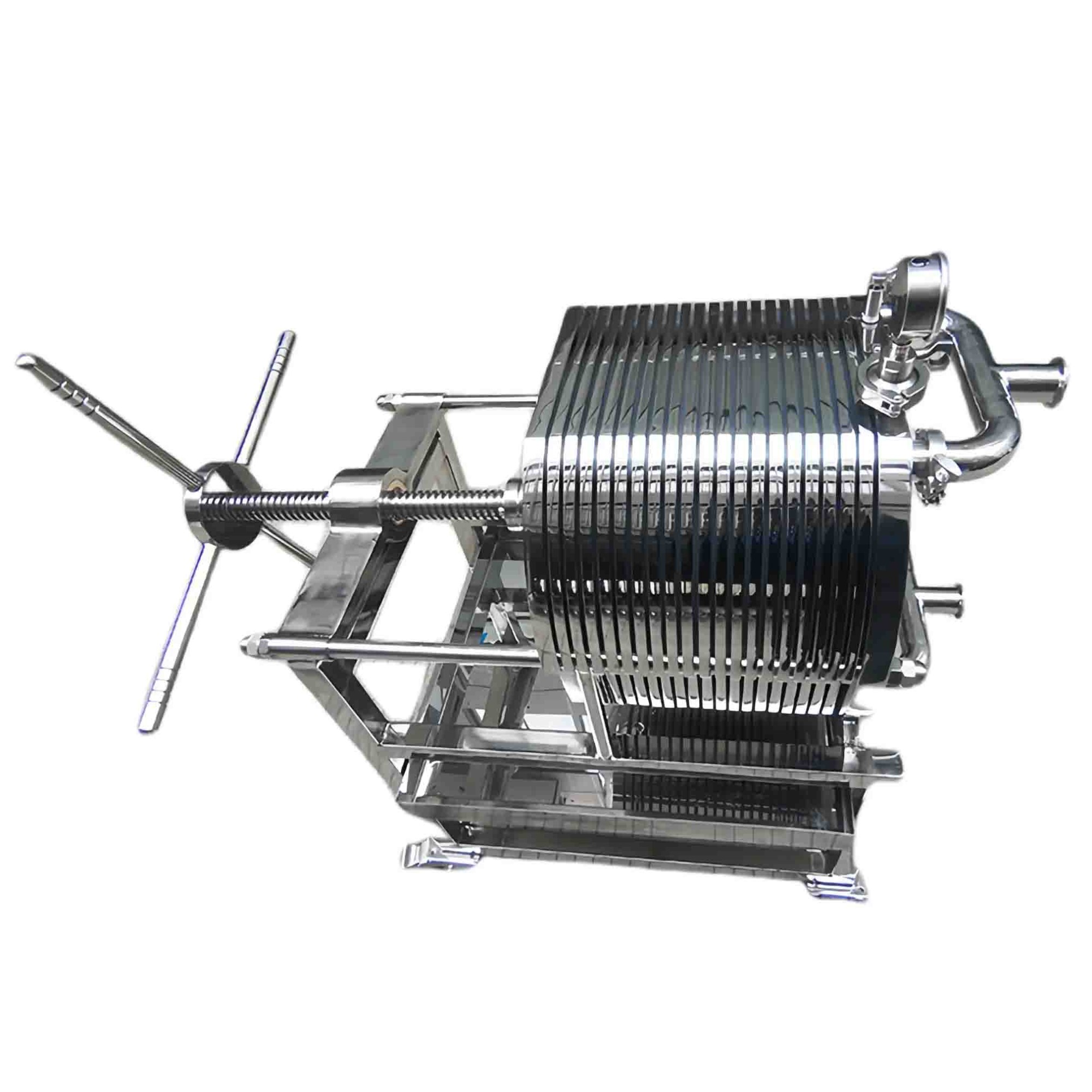

This machine is manufactured using high-quality stainless steel materials such as SUS304 or SUS316L, which are corrosion-resistant and durable. The filter plates feature a threaded structure, allowing for the replacement of different filtering materials according to the filtering medium and production process (per-filtration, semi-filtration, fine filtration). Direct use of micro-porous filter membranes can achieve sterile filtration. Users can also adjust the number of layers based on the filtration volume to meet production requirements. The machine also produces filter cloth and leak-proof plate frame filters. During operation, the machine seals and filters under pressure, resulting in no loss of liquid material, good liquid clarity, and the ability to customize multi-stage filtration devices according to user needs. The first stage can use coarser filtering materials, and the second stage can use finer materials, saving time and improving filtration accuracy. All sealing components of the machine use silicone (fluorine rubber) sealing rings, which are heat-resistant, non-toxic, leak-proof, and have good sealing performance. The machine can also be customized with an automatic return device according to user needs. When the pump stops rotating, by opening the return valve, all sediment is automatically discharged (with air exhaust function), and at the same time, the machine can be back-washed with clean water from the return pipe, which is very convenient.