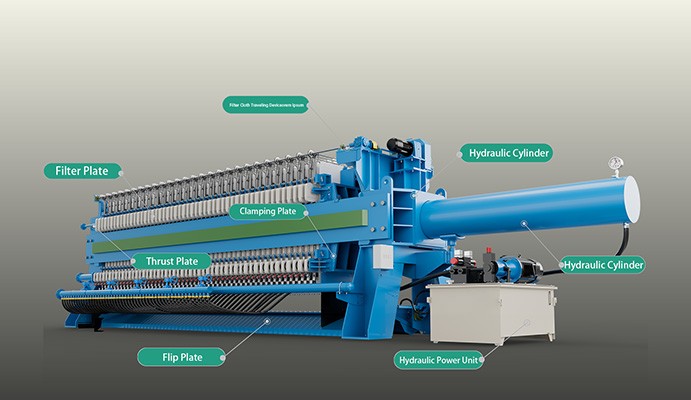

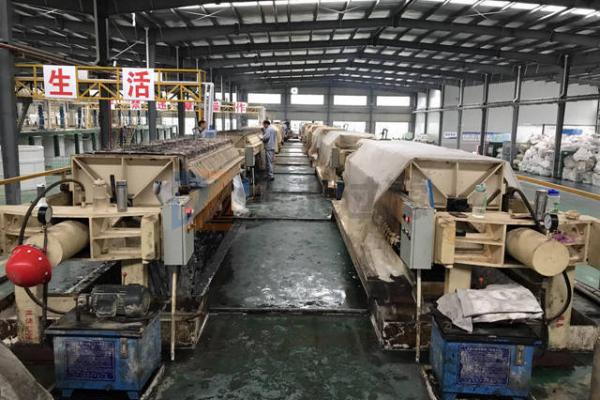

Mobile Filter Cloth Membrane Filter Press

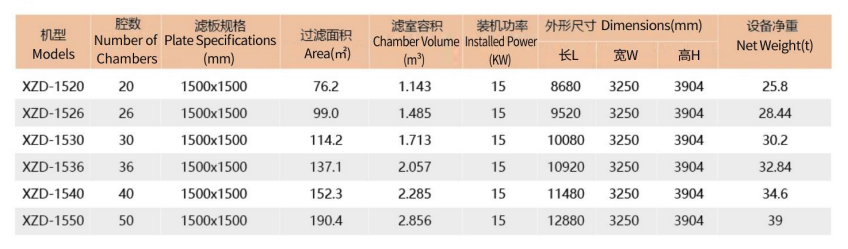

- 20-291.2

- 1100、1500

- Automatic

- Quick Open, etc.

- 0.6-4.0

- Visible/Invisible

Advantages

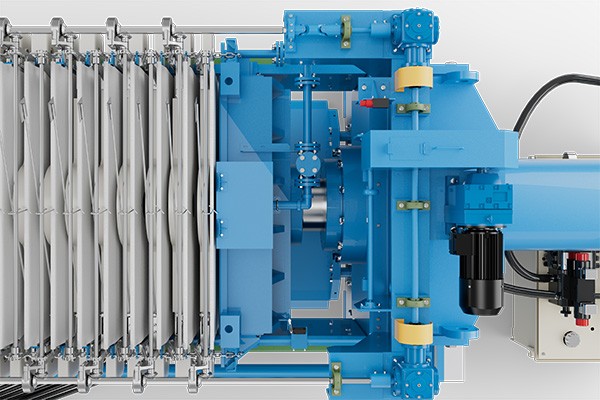

1. High degree of automation: The filter cloth can move and be cleaned automatically, reducing manual intervention.

2 . Good continuity: Discharging, cleaning, and feeding are seamlessly integrated, resulting in high efficiency.

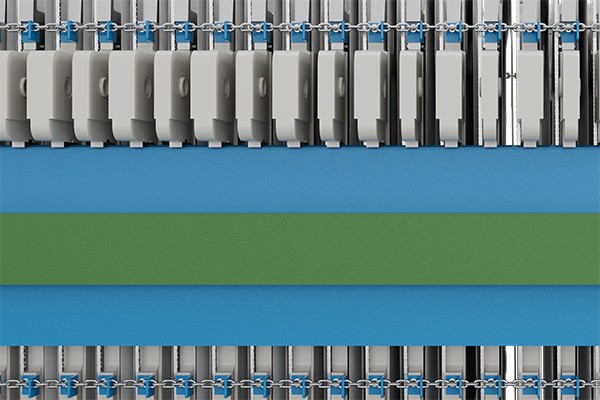

3 . High filter cloth utilization: The filter cloth is less prone to clogging and has a longer service life.

4 . Low labor intensity: Suitable for large-scale, continuous operation.

5. Stable filtration effect: Helps maintain a stable moisture content.

Disadvantages

1. High equipment cost: The Initial investment is significantly higher than that of ordinary filter presses.

2. Complex structure: Requires higher maintenance and troubleshooting expertise.

3 . Large footprint: Requires a certain amount of factory space.

4 . Slightly higher energy consumption: The filter cloth movement and cleaning system increase energy consumption.

Application areas:

The cloth-travelling filter press is widely used in mineral processing, coal slurry dewatering, metallurgical sludge, chemical slurry filtration, power plant flue gas desulfurization, gypsum, sand and aggregate slurry, as well as industrial and municipal sludge treatment. It is suitable for continuous and efficient dewatering of high-solids materials.

The Cloth-TravelingAutomatic Filter Press - our proprietary sludge dewatering technology-utilizes thin-layer dewatering principles to achieve high solids content. Without chemical additives (e.g., lime or fly ash), it reduces sludge moisture from >99% to <60% in a single step. The resulting thin, highly air-permeable filter cakes readily meet pretreatment requirements for downstream processes, including drying, incineration, landfill, and composting. This system can achieve simultaneous rapid cake discharge and cloth washing via the lifting reciprocating motion of the filter cloth. Focused on cloud platform and big data technology, it can provide a strong guarantee for machine operation and the function of fault advance warning, which greatly improves its stability and reliability. Featuring a simplified process and compact footprint, this system enables flexible retrofitting of existing facilities while aligning with industry evolution to address diverse application requirements.