Medium Temperature Drying Integrated Machine

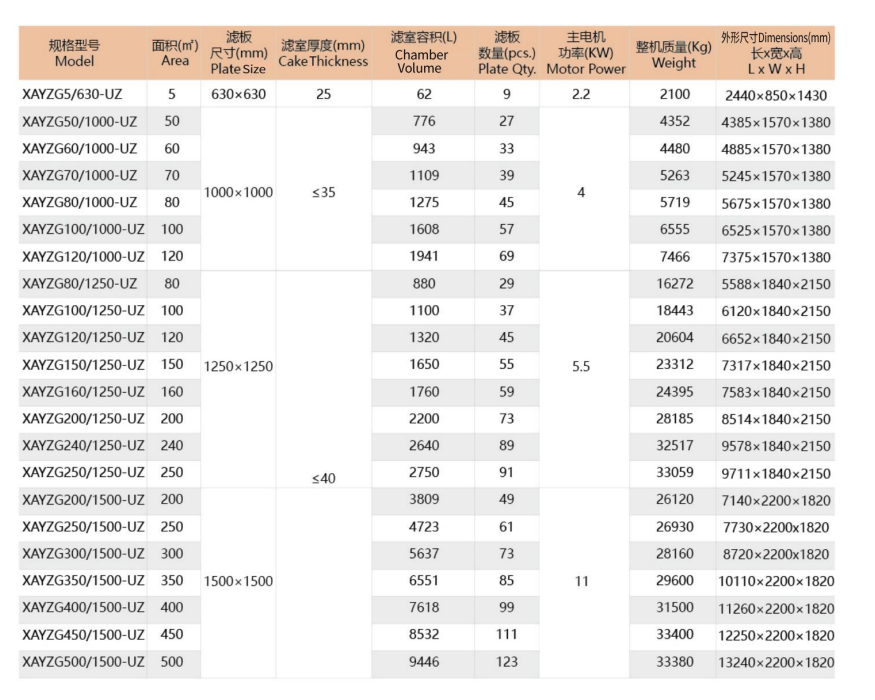

- 5-500

- 630、1000、1250、1500

- Automatic

- Open continuously

- 0.6-4.0

- Visible/Invisible

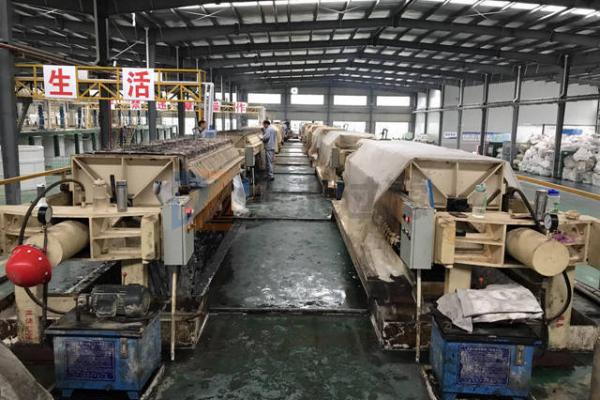

Medium Temperature Filter Press Dryer is an integrated mechanical filtration and thermal drying system, one of the solid-liquid separation equipment. It can be a one-time separation of the suspension into ultra-low liquid content rate of the dry powder and clear liquid on the unit equipment, drying the heat carrier used for more than 100 °C fluid heat medium, such as saturated steam vapor or heat.

SIMPLE PROCESS

The integrated effect of mechanical separation of suspension and thermal drying separation can be realized on the unit equipment, and the drying separation effect can be achieved at the same time.

LOW CARBON AND ENERGY SAVING

The liquid is taken off in a non-vaporizing way. The heat energy required is only to provide auxiliary power for strengthening the non-vaporizing way of separating the liquid, which is far lower than the heat energy consumed by thermal drying and vaporizing all the separated liquids. The whole system adopts thermal energy management, which saves energy by more than 60% compared with the same period of the previous year.

HIGH-EFFICIENCY SEPARATION

Controlling the vacuum and negative pressure conditions in the hot pressure chamber reduces the capillary liquid vaporization temperature, shortens the drying time, and improves the separation efficiency.