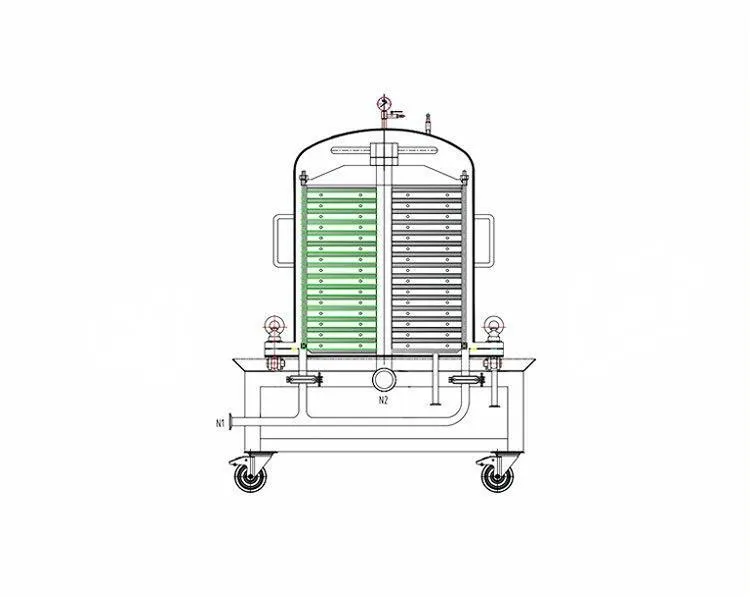

Laminated precision filter

- 10-40

- 0.2-0.4

- 0.22-100

- 0.7-20

Features

The inner shell and chassis of the equipment form a sealed inner cavity, which contains a liquid filtration device. Two raw liquid inlets and one qualified liquid outlet passing through the chassis are all connected to the inner cavity. The filtration device includes multiple overlapping filtration screen plates, dividing the inner cavity into a raw liquid chamber and a qualified liquid chamber. The raw liquid inlet and qualified liquid outlet are connected to their respective chambers. The machine features a large liquid filtration area, fast speed, large flow rate, and high efficiency within a unit space.

The equipment consists of multiple overlapping filtration screen plates. Users can choose the equipment specifications based on the processing volume. If there are temperature requirements, an insulation device can be added. Users can choose whether to equip the device with a feed pump according to their needs and can also install casters at the bottom of the equipment for easy mobility, making it a multi-purpose machine.

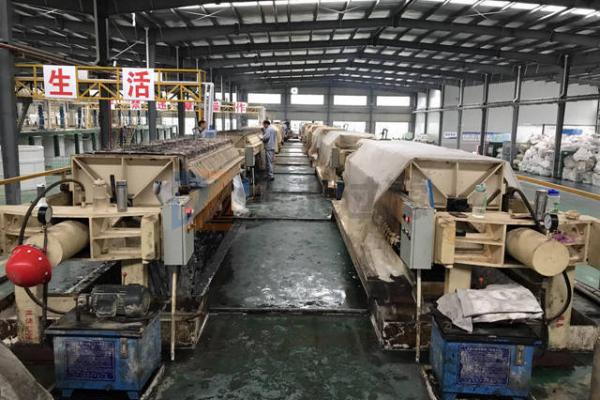

It is widely applicable to liquid filtration in industries such as chemical, pharmaceutical, fine food, and biochemistry. For materials with high solid content, the inner cavity volume can be increased to accommodate more solid particles in the raw liquid filtration as required. For filtering solvents, fluoro rubber or fluorine-encapsulated sealing pads can be used to eliminate leakage phenomena.